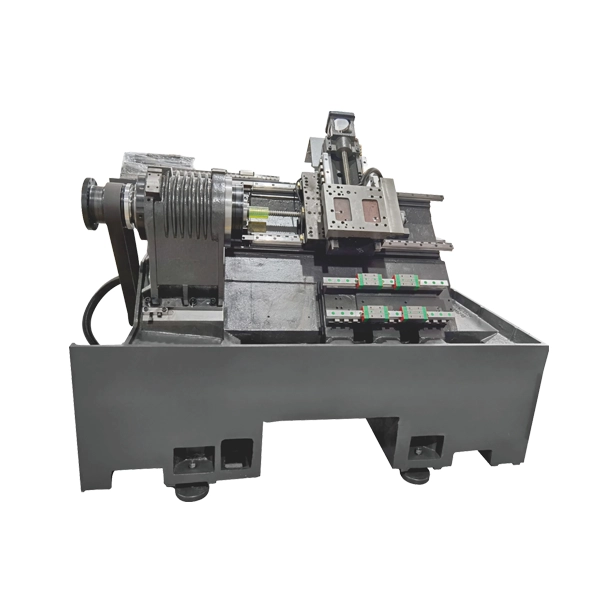

The unique and powerful mechanical structure perfectly embodies high rigidity and lasting stability

High rigidity, heavy cutting

Higher machining accuracy, more stable

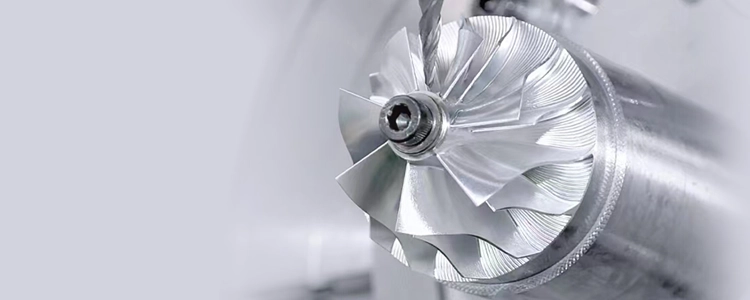

High precision, high speed spindle

High speed spindle, higher efficiency

| Specifications/Models | Unit | GL1500 | GL2000 | GL2500 | |

| Machine tool castings | Angle of inclination | ° | 45° | 45° | 30° |

Main shaft |

Spindle nose form | / | A2-5 | A2-6 | A2-8 |

| Spindle through hole diameter | mm | 56 | 61 | 87 | |

| Three-jaw chuck clamping capability | mm | 6"/φ160 | 8"/φ210 | 10"/φ254 | |

| Pull rod action form | / | Hydraulic | Hydraulic | Hydraulic | |

Numerical control system |

Numerical control system | / | Mitsubishi E80/ FANUC 0I-TF | ||

| Spindle motor power | kw | 7.5/11 | 11/15 | 15/18.5 | |

| Maximum spindle speed | rpm | 4500 | 4500 | 3500 | |

| Spindle output torque | Nm | 35.8 | 70 | 118 | |

| X-axis servo motor power | kw | 1.5 | 1.5 | 2.3 | |

| Z-axis servo motor power | kw | 1.5 | 1.5 | 2.3 | |

Processing range |

Maximum bed diameter of rotation | mm | 457 | 460 | 595 |

| Maximum length of machined workpiece | mm | 406 | 450 | 600 | |

| Maximum workpiece diameter | mm | 284 | 300 | 420 | |

| Maximum tie rod through hole diameter | mm | φ45 | φ52 | φ78 | |

| X/Z Axle | X-axis travel | mm | 150 | 210 | 275 |

| Z-axis travel | mm | 406 | 450 | 600 | |

| The X/Z axis is moving fast | m/min | 20 | 20 | 20 | |

| X/Z axis screw track | X/Z axis screw | mm | φ28/28 | φ28/28 | φ36/40 |

| X/Z axis orbital | mm | 30/30 | 30/30 | 45/45 | |

| Precision | Positional accuracy | mm | 0.005 | 0.005 | 0.005 |

| Repeated positioning accuracy | mm | 0.005 | 0.005 | 0.005 | |

| Machining roundness | mm | 0.003 | 0.003 | 0.003 | |

| Machining cylindricity | mm | 0.006 | 0.006 | 0.006 | |

| Knife tower | Knife tower drive form | / | Servo | Servo | Servo |

| The center of the tower is high | mm | 80 | 80 | 100 | |

| Knife digits | T | 8/12 | 8/12 | 8/12 | |

| Square tool holder specifications | mm | 25/20 | 25/20 | 25/20 | |

| Boring inversion specifications | mm | 40/32 | 40/32 | 40/32 | |

| Switch to time (T-T) | S | 0.3 | 0.3 | 0.3 | |

| Chip removal system | Cutting tank capacity | L | 120 | 120 | 240 |

| Cutting water pressure | bar | 2.3 | 2.3 | 2.8 | |

| Electricity demand | Voltage | Vac | 380±10% | 380±10% | 380±10% |

| Power | kw | 18 | 22 | 26 | |

| Number of Phase | phase | 3 | 3 | 3 | |

| Frequency | Hz | 50/60 | 50/60 | 50/60 | |

| Automatic tailstock | Top specification | / | / | MT4 | MT5 |

| Tailstock travel | mm | / | 350 | 625 | |

| Maximum clamping workpiece length | mm | / | 350 | 578 | |

| Machine Size | Machine size | mm | 2000*1600*1750 | 2100*1650 *1780 | 2900*1980*1800 |

| Weight | kg | 2700 | 3000 | 4500 | |

| Because technology is constantly updated, the above parameters is only for your reference | |||||