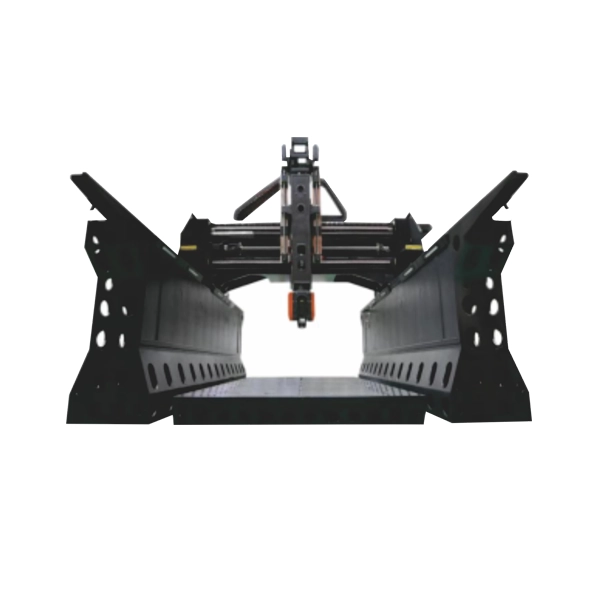

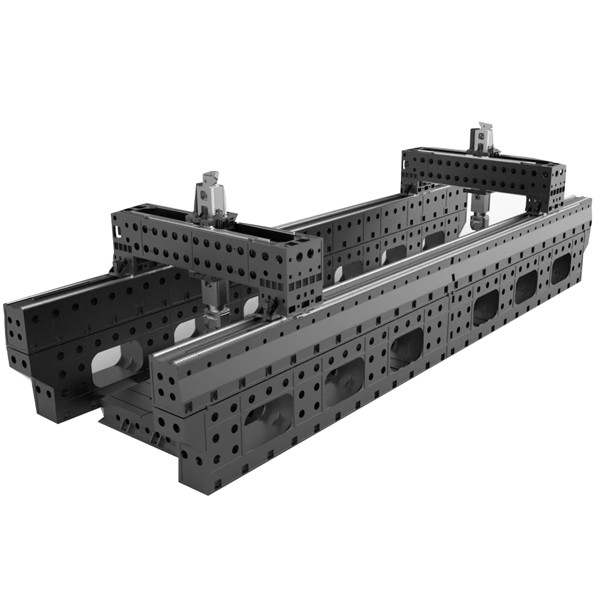

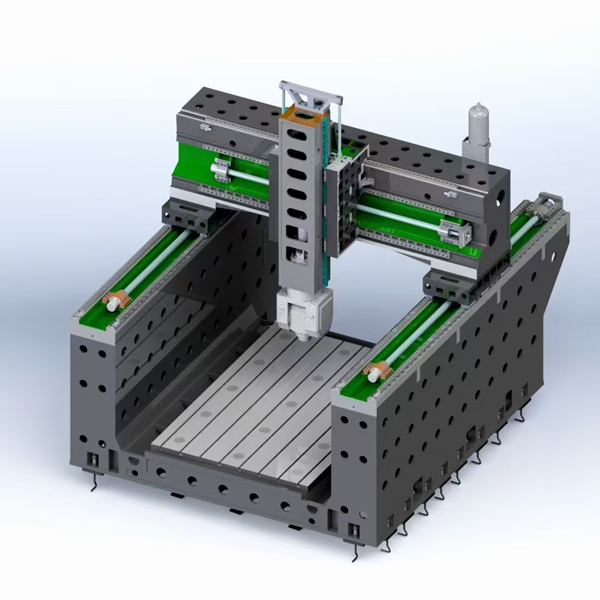

The unique and powerful mechanical structure perfectly embodies high rigidity and lasting stability

Integrated screw base and motor base to ensure high rigidity and stability.

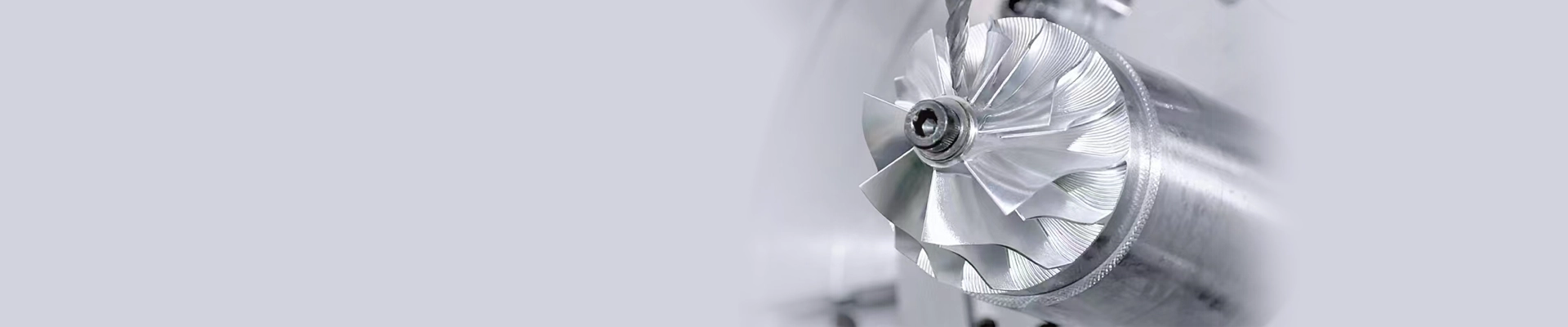

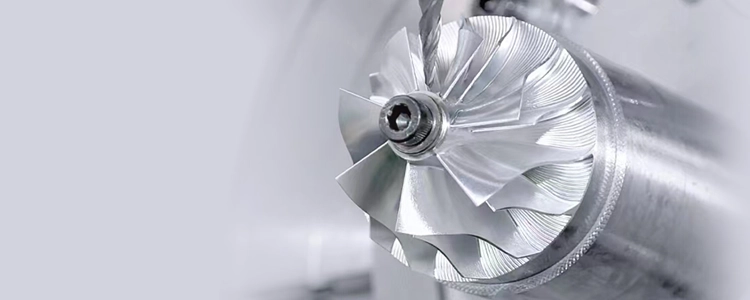

Suitable for aerospace, high precision mold, parts, 3C, 5G parts processing tool.

High-end impeller machining/surface, curve, universal machining.

| Mechanical Specification | Unit | G1625 | G2225 | G3025 | G4025 | G5025 | G6025 | |

| Processing range | X-axis stroke | mm | 1600 | 2200 | 3000 | 4000 | 5000 | 6000 |

| Y-axis stroke | mm | 2500 | ||||||

| Z-axis stroke | mm | 1000/ 1200 | ||||||

| Distance from spindle nose to table | mm | Z1,000:110~1,110/Z1,200:110~1,310 | ||||||

| mm | Z1,000:200~1,200/Z1,200:200~1,400 | |||||||

| mm | Z1,000:160~1,160/Z1,200:160~1,360 | |||||||

| mm | Z1,000:240~1,240/Z1,200:240~1,440 | |||||||

| mm | Z1,000;275~1,275/Z1,200:275~1,475 | |||||||

| mm | Z1,000:240~1,240/Z1,200:240~1,440 | |||||||

| mm | Z1,000:240~1,240/Z1,200:240~1.440 | |||||||

| mm | Z1,000:225~1,225/Z1,200:225~1,425 | |||||||

| mm | Z1,000:225~1,225/Z1,200:225~1,425 | |||||||

| Distance between columns (door width) | mm | 3,400 | ||||||

| Workbench | Area of work | mm | 1,600*2,500 | 2,200*2,500 | 3,600*2,500 | 4,000*2,500 | 5,000*2,500 | 6,000*2,500 |

| T-slot (Width x quantity x spacing) | mm | 28*11*250 | 28*15*250 | 28*19*250 | 28*23*250 | |||

| Maximum load of workbench | kg/cm² | 3,000 | ||||||

| Principal axis | Spindle | / | H810S-02-15 | |||||

| Spindle power (S1/S6) | KW | 50/65 | ||||||

| Speed of mainshaft | rpm | 12000/15000/20000/24000 | ||||||

| Taper hole of spindle | / | HSK A63/HSK-A100 | ||||||

| Spindle output torque (S1/S6) | Nm | 95.5/ 124 | ||||||

| Feed | Cutting feed rate | m/min | 1-20 | |||||

| Fast feed rate | m/min | XY:32/ Z:20 | ||||||

| Precision | Positional accuracy (JIS-B6333) | mm | ±0.005/ Full stroke | ±0.007/ Full stroke | ±0.008/ Full stroke | |||

| Positional accuracy (VD13441) | mm | P0.008 | P0.010 | P0.012 | P0.015 | |||

| Repeated positioning accuracy(JIS-B6333) | mm | ±0.002 | ||||||

| Repeated positioning accuracy(VD13441) | mm | PS0.006 | PS0.008 | PS0.012 | ||||

| Tool changer | Tool capacity | T | 20/32/40/60 | |||||

| Maximum knife diameter - Adjacent knives | mm | HSK-A63:Ф75 /HSK-A100:Ф125 | ||||||

| Maximum knife diameter - Spacer knife | mm | HSK-A63:Ф130/HSK-A100:Ф250 | ||||||

| Maximum knife length | mm | 300 | ||||||

| Max tool weight | kg | HSK-A63: 8,HSK-A100:15 | ||||||

| Machine Specifications | Weight of machinery | kg | 43,500 | 48,500 | 48,000 | 57,500 | 66,500 | 76,500 |

| Floor area (L x W x H) | m | 6.9*8.6*5.5 | 7.5*8.6*5.5 | 9.1*8.6*5.5 | 10.1*8.6*5.5 | 11.1*8.6*5.5 | 12.1*8.6*5.5 | |

| Mechanical Specification | Unit | G2232 | G3032 | G4032 | G5032 | G6032 | ||

| Processing range | X-axis stroke | mm | 2,200 | 3,000 | 4,000 | 5,000 | 6,000 | |

| Y-axis stroke | mm | 3,200 | ||||||

| Z-axis stroke | mm | 1,000/1,2000 | ||||||

| Table specification | Distance from spindle nose to table | mm | Z1,000:110~1,110/Z1,200:110~1,310 | |||||

| mm | Z1,000:200~1,200/Z1,200:200~1,400 | |||||||

| mm | Z1,000:160~1,160/Z1,200:160~1,360 | |||||||

| mm | Z1,000:240~1,240/Z1,200:240~1,440 | |||||||

| mm | Z1,000;275~1,275/Z1,200:275~1,475 | |||||||

| mm | Z1,000:240~1,240/Z1,200:240~1,440 | |||||||

| mm | Z1,000:240~1,240/Z1,200:240~1.440 | |||||||

| mm | Z1,000:225~1,225/Z1,200:225~1,425 | |||||||

| mm | Z1,000:225~1,225/Z1,200:225~1,425 | |||||||

| Distance between columns (door width) | mm | 3,900 | ||||||

| Workbench | Area of work | mm | 2,200 *3,200 | 3.000*3,200 | 4,000*3,200 | 5,000*3,200 | 6.000*3.200 | |

| T-slot (Width x quantity x spacing) | mm | 28*13*250 | 28*11*250 | 28*15*250 | 28*19*250 | 28*23*250 | ||

| Maximum load of workbench | kg/cm² | 3,000 | ||||||

| Principal axis | Spindle type | / | H810S-02-15 | |||||

| Spindle horsepower (S1/S6) | kw | 50/65 | ||||||

| Speed of mainshaft | rpm | 15,000 | ||||||

| Taper hole of spindle | / | HSK-A100 | ||||||

| Spindle output torque (S1/S6) | Nm | 95.5/ 124 | ||||||

| Feed | Cutting feed rate | m/min | 1-20 | |||||

| Fast feed rate | m/min | XY:32/Z:20 | ||||||

| Precision | Positional accuracy (JIS-B6333) | mm | ±0.005/Full stroke | ±0.007/ Full stroke | ||||

| Positional accuracy (VD13441) | mm | P0.008 | P0.010 | P0.012 | P0.015 | |||

| Repeated positioning accuracy(JIS-B6333) | mm | ±0.002 | ||||||

| Repeated positioning accuracy(VD13441) | mm | PS0.006 | PS0.008 | PS0.012 | ||||

| Automatic tool change | Tool magazine | pcs | 20/ 32/ 40/ 60 | |||||

| Machine Specifications | Weight of machinery(about) | kg | 46,000 | 45,500 | 55,500 | 64,000 | 73,500 | |

| Floor area (L x W x H)(about) | m | 7.5*9.1*5.5 | 9.1*9.1*5.5 | 10.1*9.1*5.5 | 11.1*9.1*5.5 | 12.1*9.1*5.5 | ||

| Because technology is constantly updated, the above parameters is only for your reference | ||||||||